The Revolution of HDS-3D Laser Scanning Unveiled!

Changing times not only bring development and progress but also result in revolution. Revolution can define changes, transform and introduce advancements. This is what has been proven in the field of surveying using High Definition Surveying (HDS) technology.

Slow Yet Effective Transition of Terrestrial Laser Scanning

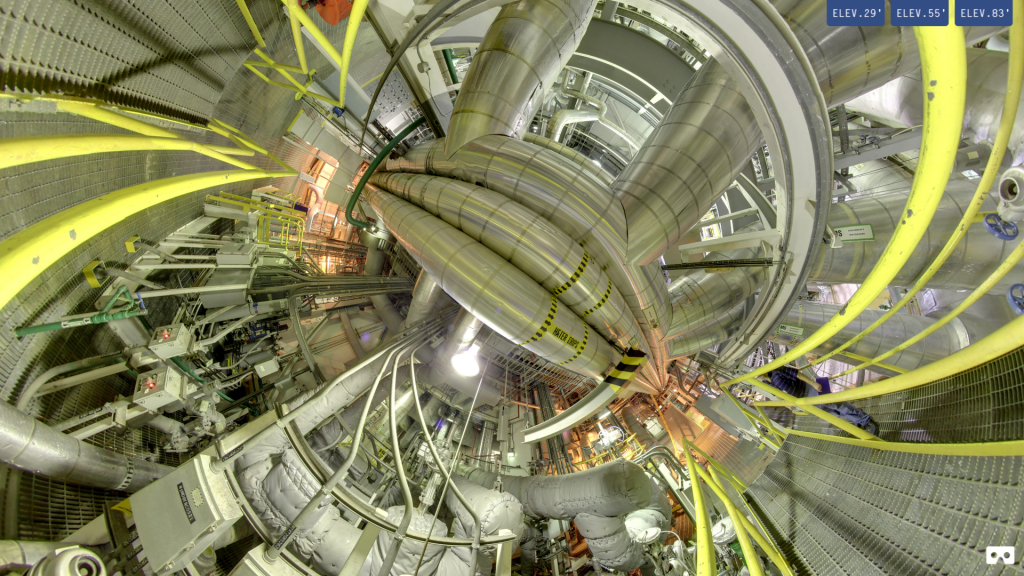

Engineers and designers would have never thought a decade ago that an existing structure or facility can be brought on to their desktop in 3D without them needing to leave the office. While conventional surveys provided just enough information on as-is, as-built projects, HDS provides millions of measurements for the entire vicinity leaving zero room for speculation. A terrestrial laser scanner is a device that is mounted on a tripod and actively scans the surrounding environment while logging pointcloud (dense points in space) by using range finding techniques. Pointcloud is the set of data points that are identified by a coordinate system and represent a 3D shape or feature. HDS encompasses the technique used in terrestrial laser scanning.

The development of Terrestrial Laser Scanning reduced the dependencies on manual checks. Soon, the introduction of TPS in the 1980s further sparked the revolution. The 90s saw the birth of GPS. Then came –LiDAR also termed as – Light Detection and Ranging Technology. All this led to the continuous advancement of technology in the surveying industry.

What Made HDS Special?

High Definition Surveying (HDS) is capable of encapsulating millions of points per second. With the help of a laser beam, it can take images continuously in real time scenario. It can capture data with exact positions, which could be about thousands and millions of measurements with accurate 3D-axis(x, y, and z) coordinates of each.

HDS can also capture various other parameters like the color of the objects, depth, length, and breadth of the object along distance from the laser scanner.

- HDS provides accurate and hassle-free data surveys with reduced risks and lowered costs.

- It provides detailed, fast, accurate and complete surveys that you seldom have to go for a site revisit.

- However, if you tend to lose some info, or need more details, you can always visit the scanned scene virtually.

- Since the data is digital, you can further make the most out of it by using various software. You might see a proposed design in CAD in a real-world context and so on.

Therefore, with HDS, now you have flawless, real-time, three-dimensional data with speed and accuracy. The presence of highly reliable data makes you work faster, thus saving time and cost both for you and your client.

What is HDS and How it Works?

You may understand HDS as High Accuracy Mapping, Capturing/Scanning Reality, or 3D Laser Scanning. HDS just does not capture specific points one at a time, instead, it captures the whole scene at 360 degrees. It can be understood as a camera taking a 360-degree picture in one go. The best part is this picture has precise details of each pixel of the photo. Another good thing about HDS is that the pixels can be expanded further to get more details on that point, which means that the picture can be magnified many times for clarity.

So, how does this work?

Three Step Process for 3D Laser Scanning

1. Field Job

HDS equipment is deployed to the site of interest. The orientation of the equipment is decided by optical leveling, and by the scanner operator. HDS equipment usually captures 360 X 270-degree view; creating a cupola or hemisphere of point clouds.

HDS equipment or the scanner scans the entire area and stitches various scenes at the site location to present a combined and complete view of the site. This, therefore, makes it easy for the engineers to visualize and conceptualize.

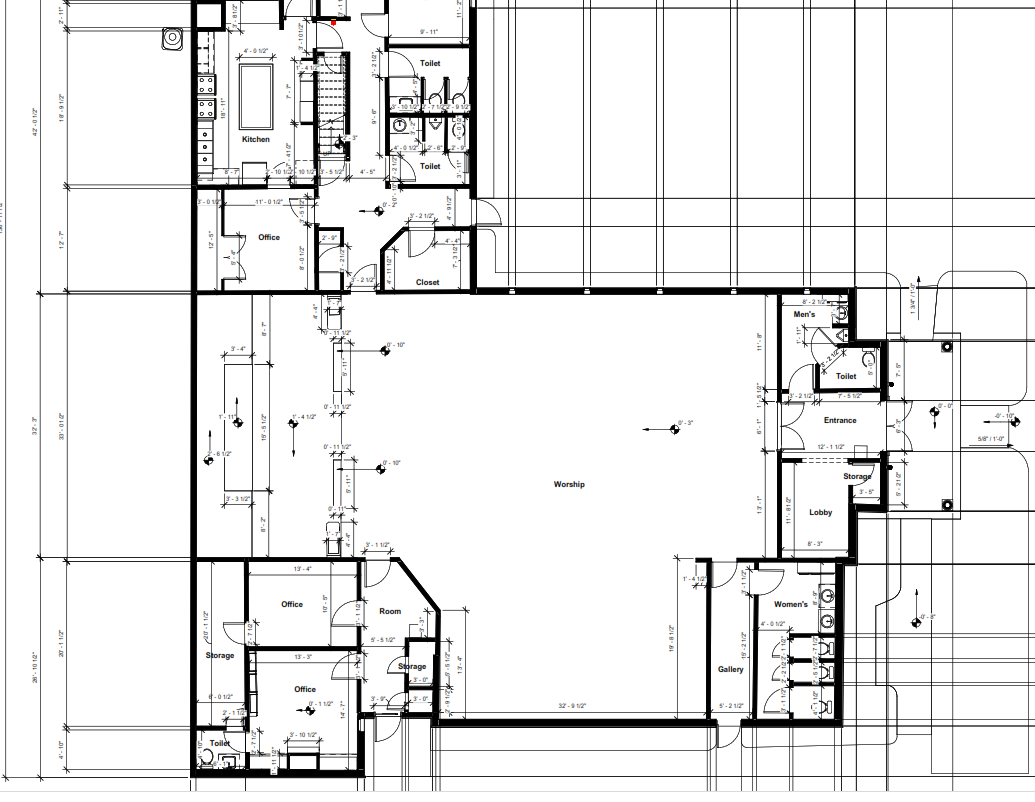

The detailing is accurate to the smallest possible point and coordinate data is collected for each such point. This helps in capturing 3D as-builts for any building site, or construction project.

The data collected is a real-time data, also termed as “as-built” information with 100% accuracy. Therefore, the possibility of any loss of data is impossible. With such fast and accurate data, you not only tend to save your time and cost, but also save the hassles of repeated visits to the site.

The HDS instrument can perform monitoring surveys, volumetric surveys, pre-event planning, and forensic surveys, with a great precision. This not only enables better planning but also helps you in viewing the site from various angles, which would not have been possible through physical inspection

2. Software

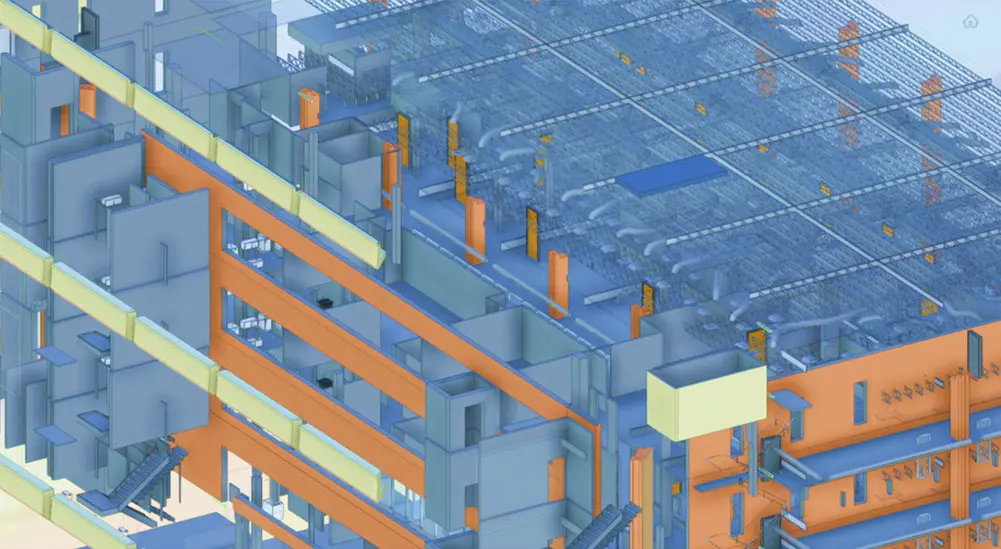

The data collected by the HDS equipment is then fed to software to get images of the scene or site. The conversion of data can be done in the form of two-dimensional models or a three-dimensional model. Panoramic pictures taken can also be used for better visualization of the site or plant.

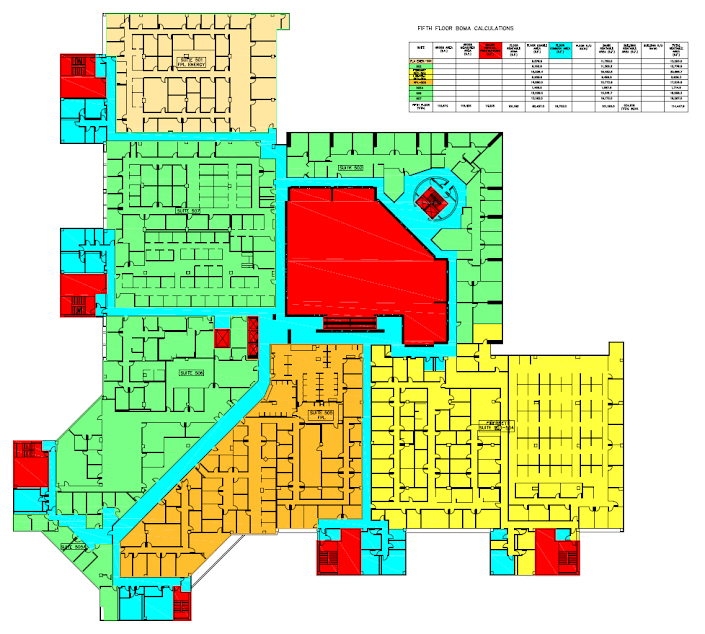

HDS makes it is easier for the surveyor to explain details to the project stakeholders, as the data collected is Geo-referenced. This means you get details of length, width, height, volumetric reports, clearances, a line of sight, and trajectory analysis.

3. Derived Solution

Once the data is analyzed, engineers can sit along with clients for a better understanding of problem statement. This allows them to work with reduced time, space, manpower, cost and swift planning. The delivery of solution is fast and as it is a real-time experience, it can be done without actually moving out of the office. The possibilities of the solutions can be checked and verified before it actually happens at the site.

As the data can be converted into 3D visual models, that can be viewed from various angles, the project team can virtually collaborate in 3D space that is scaled, textured and resembles the real environment.

In Closing…

The technological advancement with HDS is fast, accurate and detailed, thus, saving cost and time, in addition to increasing business efficiency, and revenue for both you and your client.

HDS is a boon for industries like architecture, engineering, construction, infrastructure, oil and gas, and telecommunications, where the need for surveying and engineering go side-by-side.

The possibilities with HDS are immense and are slowly being understood by different sectors and industries. The days are not far when further technological developments will take HDS to new dimensions, and the scope of this technology will widen. That advancement will then be the next evolution in the history of 3D scanning and imaging, and of course mankind.

At Reality Imaging and Mapping Technologies, we have been harnessing the best out of HDS technology,by providing accurate 3D as-builts for our valued clients. To learn more, drop us a message and we will be happy to schedule a demo for your team.